Glass Wool vs Rock Wool: A Comparative Analysis

Glass Wool vs Rock Wool

Glass Wool

Rock Wool

In the realm of insulation materials, glass wool and rock wool are two of the most prominent options. Both materials offer distinct benefits and are widely used in various industries, from construction to manufacturing. This article provides a comprehensive comparison between glass wool and rock wool, examining their properties, applications, and overall performance.

Composition and Production

Glass Wool

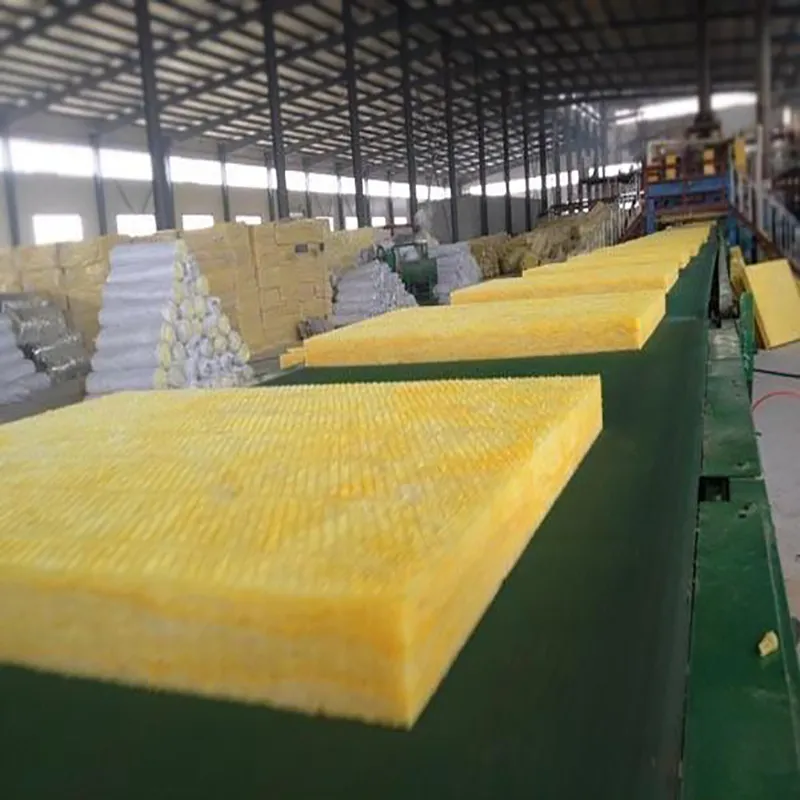

Glass wool is made from recycled glass and sand, which are melted and spun into fine fibers. These fibers are then bound together using a resin to form a mat, which can be cut into various shapes and sizes. The process results in a lightweight, fibrous material with excellent thermal and acoustic properties.

Rock Wool

Rock wool, also known as mineral wool, is produced from natural basalt rock and recycled slag. These materials are heated to high temperatures and spun into fibers, which are then bonded together with a resin binder to create dense, rigid boards or flexible blankets. Rock wool is known for its superior fire resistance and durability.

Thermal Insulation

Both glass wool and rock wool provide excellent thermal insulation, but their performance varies slightly due to differences in density and composition.

- Glass Wool: Offers low thermal conductivity, making it highly effective in preventing heat loss and gain. It is commonly used in residential and commercial buildings for insulation in walls, roofs, and floors.

- Rock Wool: Also boasts low thermal conductivity, but its higher density can enhance its insulating capabilities in certain applications. It is particularly suitable for industrial settings where maintaining stable temperatures is crucial.

Fire Resistance

Fire resistance is a critical factor in choosing insulation materials, and here, rock wool has a distinct advantage.

- Glass Wool: While it can withstand high temperatures, glass wool begins to melt at around 700°C and may release toxic fumes in the event of a fire.

- Rock Wool: Can endure temperatures exceeding 1000°C without melting or emitting harmful gases. Its non-combustible nature makes it an ideal choice for fire-rated constructions and industrial applications requiring stringent fire safety measures.

Acoustic Insulation

Both materials offer sound absorption properties, but their effectiveness can differ based on specific requirements.

- Glass Wool: Its lightweight, fibrous structure effectively reduces noise transmission, making it suitable for residential buildings, offices, and schools where noise control is important.

- Rock Wool: Its denser composition provides excellent sound insulation, particularly in environments with high noise levels, such as factories, theaters, and recording studios.

Moisture Resistance

Resistance to moisture and mold growth is another important consideration for insulation materials.

- Glass Wool: Generally resistant to moisture, but prolonged exposure can reduce its insulating properties and lead to mold growth if not properly installed.

- Rock Wool: Highly resistant to moisture and water absorption, maintaining its performance even in damp conditions. This makes it ideal for use in basements, bathrooms, and other areas prone to humidity.

Sustainability

Both materials are environmentally friendly options, but their sustainability profiles have slight differences.

- Glass Wool: Made from recycled glass, it is an eco-friendly option with a lower environmental impact. However, the production process can be energy-intensive.

- Rock Wool: Utilizes abundant natural resources and recycled content. It is fully recyclable and has a longer lifespan, which contributes to its sustainability.

Applications

- Glass Wool: Predominantly used in residential and commercial buildings for thermal and acoustic insulation. It is also used in HVAC systems, ductwork, and lightweight partitions.

- Rock Wool: Used in a wide range of applications, including building insulation, industrial insulation, fireproofing, and acoustic panels. Its durability and fire resistance make it suitable for more demanding environments.

In conclusion, both glass wool and rock wool are excellent insulation materials with unique advantages. Glass wool is lightweight, effective for thermal and acoustic insulation, and environmentally friendly. Rock wool offers superior fire resistance, durability, and moisture resistance, making it suitable for industrial applications and fire-rated constructions.

Choosing between the two depends on specific project requirements, such as thermal performance, fire safety, acoustic control, and environmental impact. By understanding the strengths and limitations of each material, architects, builders, and engineers can make informed decisions to achieve optimal insulation solutions.

English

English

Roof Thermal Insulation with Aluminum Foil Veneer Glass Wool Board: A Smart Solution for Energy Efficiency

As energy costs rise and the demand for sustainable building solutions increases, roof thermal insulation has become a critical aspect of modern construction. One of the most effective materials for achieving superior insulation is the Aluminum Foil Veneer Glass Wool Board. This advanced insulation solution combines the thermal efficiency of glass wool with the reflective properties of aluminum foil, offering enhanced performance for roofing applications.

Read MoreRecycled Glass Wool Blanket for Building Insulation: A Sustainable Solution

As the demand for eco-friendly building materials increases, Recycled Glass Wool Blanket has emerged as an excellent choice for building insulation. Made from recycled glass, this material offers an environmentally responsible alternative to traditional insulation options, helping reduce waste while improving energy efficiency in homes and commercial buildings.

Read MoreEco-Friendly Materials: Glass Wool Blanket for Sustainable Insulation

As the world becomes more focused on sustainability and reducing environmental impact, eco-friendly materials have gained significant importance in construction and manufacturing. One such material that stands out in both environmental performance and versatility is Glass Wool Blanket. Made from recycled glass, this sustainable insulation solution offers a variety of benefits that help reduce energy consumption while contributing to a greener future.

Read More